Automated CNC Equipment

Customized And Integrated for Optimal Production

Optimize your facility with a custom system for automated machining

Use the Right Tool for the Job

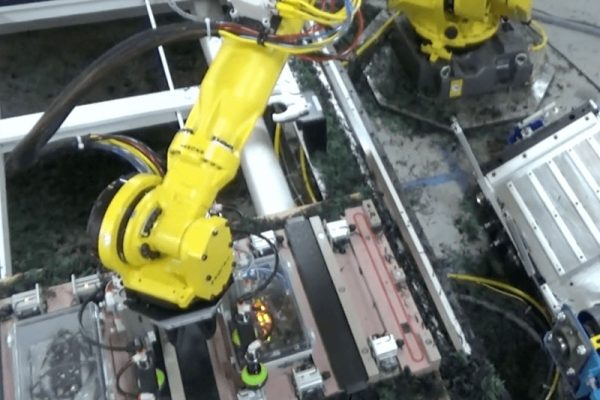

Integrate the Work Cell

Integrating CNC equipment into a multi-function work cell can significantly improve efficiency by simplifying part transfer and simultaneously completing tasks. Expert programming can determine and command the system to perform at optimal efficiency.

Streamline Your Process Flow

Combining standard CNC equipment with components such as material handling and inspection systems may provide the best optimization of your process flow. Robots can load and unload parts. Vision systems can inspect for quality and process monitoring can keep track of tool wear.

Optimized CNC Machining Solutions

CNC Router Integration

An Onsrud CNC Router is integrated into a fully automated work cell. The system incorporates robotic tending, a custom feeding system, automatic fixture assembly, and an air nailer with inspection.

- CNC integration

- Pendulum processing

- Multi-function work cell

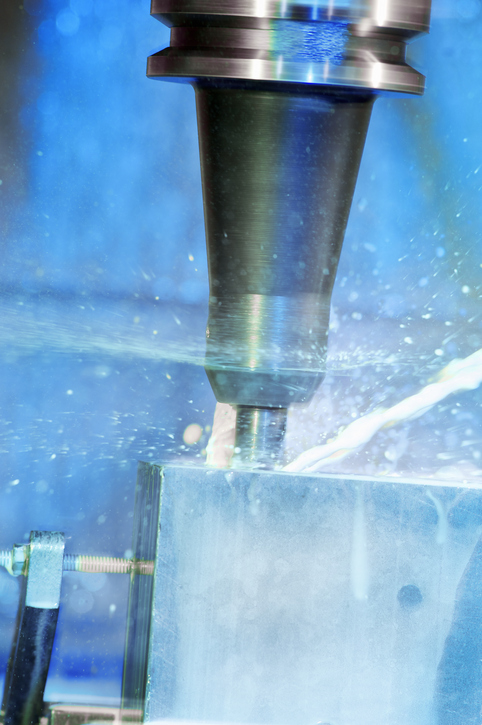

CNC Foam Milling

A custom gantry-style milling system cuts polystyrene, modeling board, or other medium density materials. An automated debris evacuation system keeps the work area free from excess material. The system can be operated unattended for “lights out” productivity.

- Through-spindle debris evacuation

- Large work envelope (18’x12’x4’)

- Automated tool changers

Ready to Optimize your production with a Custom CNC Solution?

1. Talk With A Specialist

Schedule a complimentary meeting with our automation specialists. This is your opportunity to ask questions about our automation process, and for us to gain more clarity about your needs.

2. Initiate Your Custom Automation Solution

Criterion's proven process which includes multiple collaborative discussions between you and our team will result in an automation solution that achieves your goals. Frequent progress updates will free you to focus on other priorities knowing that your project will be successfully implemented.

3. Save Time, Money, and Labor

At the end of the project, you'll have a custom solution in place and our expert service team available if you need us. You will reliably manufacture quality products on time.

Case Study: CNC Router for Therma-Tru Doors

Therma-Tru is a leading manufacturer of doors. To offer their customers the option of purchasing made-to-order doors, Therma-Tru turned to Criterion to provide a custom CNC Door Router. Driven by individual orders, panels are cut in either fiberglass or metal clad doors using automated tool selection. Scrap removal is integrated within the design. A custom infeed system automatically adjusts to accommodate a wide variety of sizes and prevent injury. A poka yoke mechanism insures the correct parts have been loaded.