When designing and building custom automation equipment, the ability to quickly prototype and test concepts is critical to keeping projects on schedule, within budget and ultimately successful. At Criterion, we’ve been perfecting the 3D printing of prototypes and production parts for more than five years. 3D printing has made the prototyping and testing process easier and more efficient than ever before.

What follows are just a few of the benefits we can offer our customers with help from our mastery of 3D printing.

Time savings. With rapid prototyping, we’re able to manufacture concepts in-house, conduct testing, make design changes, and manufacture an updated design all in a few days—a process that took weeks only a few years ago. As 3D printing shortens our design process, we can get our customers’ new automation systems up and running sooner than ever before.

Risk reduction. 3D printing provides increased quality and consistency and makes it easier to achieve proof of concept. In some cases the prototype becomes the final part or product, further shrinking the gap between the solution that was tested and the one that’s ultimately put into service. In other cases, refined testing with the help of 3D printed prototypes lets us zero in on the exact industrial equipment to specify when automating a client’s process.

Innovative solutions. In some cases, 3D printing lets us develop solutions that may not have been possible using traditional manufacturing methods—and oftentimes they’re as easy to implement as they are innovative. The use of 3D printing opens up all kinds of opportunities to solve problems in ways that just weren’t possible a few short years ago.

Cost savings. From lowering the costs of prototyping and testing to reducing material, labor and time requirements, all kinds of cost savings are made possible by 3D printing. In some cases, 3D printed parts are able to accomplish what might otherwise have required a large capital equipment outlay, allowing for additional cost savings.

Criterion 3D Printing in Action

The following examples help illustrate some of the ways we use 3D printing as a vital part of our engineering process.

Example #1: Getting the Specs Just Right

The progression of a solution can clearly be seen in this series of prototypes we printed (right). The objective was to test a solution that would use air to help an operator invert a cushion after sewing. 3D printing allowed us to create these adapters for our in-house Shop-Vac in order to test part geometry and airflow requirements. By determining the exact specifications—all without an excessive investment of time, materials, or labor—we were able to specify the exact piece of industrial equipment required to make the final solution a success.

The progression of a solution can clearly be seen in this series of prototypes we printed (right). The objective was to test a solution that would use air to help an operator invert a cushion after sewing. 3D printing allowed us to create these adapters for our in-house Shop-Vac in order to test part geometry and airflow requirements. By determining the exact specifications—all without an excessive investment of time, materials, or labor—we were able to specify the exact piece of industrial equipment required to make the final solution a success.

Example #2: Printing the (Previously) Impossible

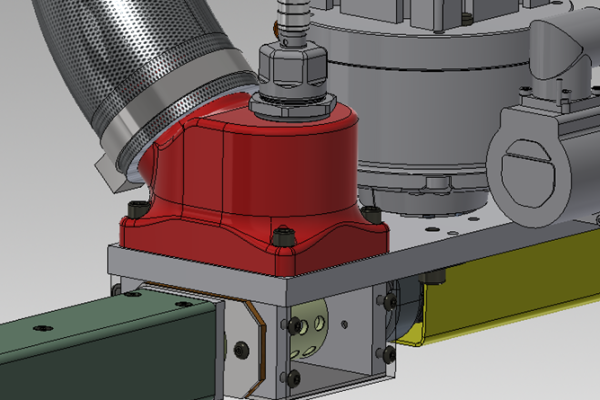

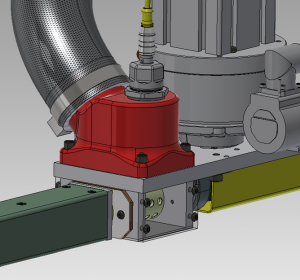

In more and more cases, we’re printing parts that would be impossible to make with traditional machining methods. We recently designed and printed a part (shown in red, left) for an end-of-arm tool that picks up strips of fiberglass. The part adapts a vacuum tube to a chamber and allows a pressure sensor to thread into its top in order to read the vacuum level. By 3D printing this part we were able to angle the tube and sensor in a convenient way that wouldn’t have been possible with traditional machining methods.

In more and more cases, we’re printing parts that would be impossible to make with traditional machining methods. We recently designed and printed a part (shown in red, left) for an end-of-arm tool that picks up strips of fiberglass. The part adapts a vacuum tube to a chamber and allows a pressure sensor to thread into its top in order to read the vacuum level. By 3D printing this part we were able to angle the tube and sensor in a convenient way that wouldn’t have been possible with traditional machining methods.

Example #3: The $.28 Part

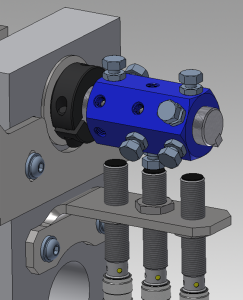

A recent project required a way for proximity sensors to verify a rotating shaft’s orientation. We designed and printed a part (shown in blue, right) that fits on the end of the shaft and has bolts threaded into it, which are presented to the proximity sensors. The part was printed in a few hours with only three minutes of prep time, at a material cost of $0.28. If the same part were made of aluminum, it would take more than five hours for a manual machinist to complete, costing $5 in materials and 100x more than that in labor costs.

A recent project required a way for proximity sensors to verify a rotating shaft’s orientation. We designed and printed a part (shown in blue, right) that fits on the end of the shaft and has bolts threaded into it, which are presented to the proximity sensors. The part was printed in a few hours with only three minutes of prep time, at a material cost of $0.28. If the same part were made of aluminum, it would take more than five hours for a manual machinist to complete, costing $5 in materials and 100x more than that in labor costs.

While 3D printed threads of the kind used in examples #2 and #3 aren’t ideal for applications where a bolt needs to withstand a lot of force, they can hold more than one might think at first glance. Stay tuned for a future blog post where we’ll reveal how to get the most strength out of fasteners threaded into 3D printed parts (hint: the use of the correct thread inserts, percent infill, and print orientation makes all the difference).

Using the Latest Technology to Deliver Innovative Solutions

From 3D printing to artificial intelligence and more, the Criterion engineering team masters and employs the latest technology to deliver the most innovative, effective automation solutions to our customers. Regardless of what technology goes into developing your custom solution, you can be sure it will help make your production process easier, safer and faster. To find out how Criterion can help you meet your business needs, contact us at [email protected].