Brinkley RV, designer and manufacturer of premium travel trailers and luxury fifth wheels, is setting new standards of quality in its industry. When the Brinkley team set out to upgrade its vehicle vibration testing system, they chose to work with the ‘creative engineering minds’ at Criterion Automation, says Kevin Lehman, Brinkley RV’s EHS, maintenance and facilities manager.

The Challenge

Brinkley wanted a turn-key system that would simulate a range of road conditions, provide a repeatable and programmable testing protocol, and produce measurable results for each coach tested. The system needed to be flexible and easy-to-use, ensure worker safety, and support quality control as well as R&D.

“Brinkley has very high quality standards,” says Jeanne Rathbun, Criterion CEO. “They are committed to using the latest technology to thoroughly test every RV leaving their facility.”

Criterion’s Process

As part of Criterion’s comprehensive discovery process, our engineers gained a clear understanding of Brinkley’s complete line of coaches and their current and future testing needs. Multiple internal and customer reviews took place as the Criterion team applied its extensive vehicle testing, quality control equipment, and systems integration experience to develop a solution.

“Communication was great during this entire process,” says Lehman. “I never had to worry about having a question answered or having enough onsite technical support. The Criterion team was great to work with.”

Criterion’s Solution

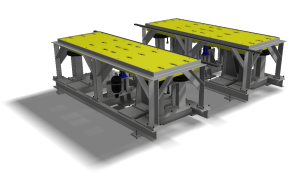

Criterion designed a vibration testing system that allows a wide range of amplitude and frequency settings. Tests can simulate gentle rocking motion, fast vibrations, high-acceleration, or low-frequency motion that is not possible with a typical shaker based on oscillating weight. Separate left and right axes can generate rocking motion, which is the most strenuous test condition for coaches. Pre-programmed recipes make the process simple for operators.

“The system performed exactly as I anticipated,” says Lehman. “Criterion exceeded our expectations in terms of the hassle-free installation of the system and their attention to detail to the equipment’s fit and finish. The overall performance has been great. We’re excited that this equipment works not only for testing but will also be very helpful in R&D.”

Results

The system provides a full range of benefits for Brinkley as they thoroughly test every RV. Benefits include:

- Superior quality control for each individual vehicle

- A robust test protocol that more closely simulates actual road conditions

- Enhanced worker safety, thanks to the elimination of hazards and pinch points typically present in similar systems

- Easier above-ground maintenance

- Flexibility via multiple programmable testing scenarios that provide a variety of test results

- Ease of use as operators can select pre-programmed recipes from the PC-based user interface, following guidance from project engineers

- Ability to automatically sequence through a series of tests, specifying duration, frequency, amplitude, and phase angle setpoints.

- Documentation of test results tracked to individual vehicles

“We are excited to see this robust and versatile vibration testing system in action and for playing a part in supporting Brinkley as they continue to set a high standard of quality excellence in their industry,” said Rathbun.

What Challenge Can Criterion Solve for You?

Manufacturers of all kinds count on Criterion to automate their quality inspection, assembly, and machining processes making it easier, safer and faster for them to produce quality products. Let’s talk about what Criterion Automation can do for you. Contact us today.